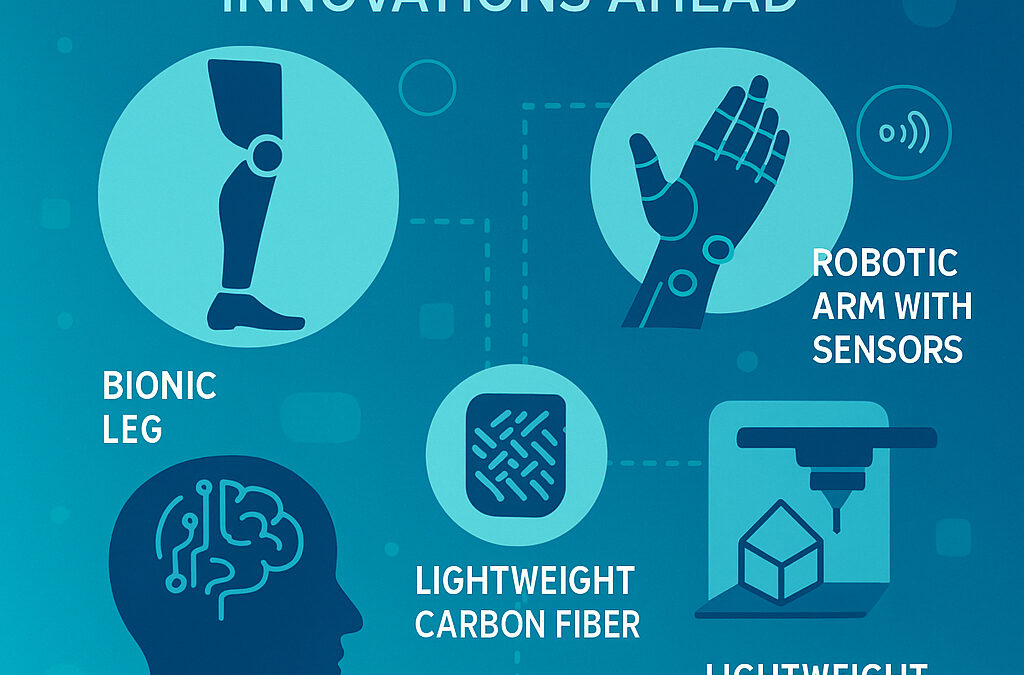

Prosthetic technology is evolving rapidly—driven by advances in materials, neuroscience, robotics, AI, and manufacturing. These developments are pushing toward prosthetics that feel more natural, are more responsive, last longer, and adapt better to individual users. Here are some of the most exciting innovations to watch in the near future, and how they could change the lives of amputees.

- Nervous System / Biomechanical Interfaces & Embodiment

- Agonist-Antagonist Myoneural Interface (AMI): This approach reconstructs or preserves muscle relationships around amputation sites so that muscles can send and receive signals in pairs. This gives more control, improves movement nuance, reduces phantom pain, and increases the feeling that the prosthetic is part of the body. It features centrally in many trials of brain-controlled prosthetic legs.

- Osseointegration + Implanted Electrodes: Instead of using sockets, prosthetics are being anchored directly to the bone (osseointegration) and connected via implanted electrodes into muscles. This improves stability, reduces discomfort, and can allow more precise control.

- Neural Interfaces & Sensory Feedback: Work is ongoing to give users more natural feedback — touch, pressure, temperature — through neural or intraneural stimulation. Being able to sense what your prosthesis is doing helps improve control, reduce overuse injuries, and increase confidence.

- Smarter Control Systems & AI

- Machine Learning & Pattern Recognition: Prosthetic limbs are getting “smarter” in how they interpret signals: distinguishing between muscle contractions, movement intention, grip strength, adapting to different terrains, etc. Algorithms learn over time from how the user moves.

- Mind-controlled Prosthetics / Brain-Computer Interfaces (BCIs): Controlling a prosthetic with thought via sensing brain or muscle signals is closer to mainstream than ever. Research from labs such as MIT show that brain-driven legs can restore more natural walking speeds and better handling of stairs/obstacles.

- Advanced Materials & Design

- Lighter, Stronger Composites: Carbon fibre, advanced polymers, lightweight metals (titanium alloys), smart materials that adapt under load are being used more widely. They balance strength and durability without making limb too heavy.

- 3D Printing / Additive Manufacturing: Customisation is improving via 3D printing. Prosthetic parts and sockets can be tailored to shape, size, cosmetic preferences, and even modified easily if the user grows or circumstances change. This also helps reduce cost and lead time.

- Cosmetic Realism & Comfort: Advances in materials for cosmetic covers (skin tone matching, texture), improved liners, socket comfort, sweat/wipe-away surfaces, better fit to avoid chafing and discomfort.

- Pediatric & Growth-Adaptive Prosthetics

Kids grow fast, and prosthetics for children must adapt. Near-future prosthetics will more often include:

- Replaceable or adjustable parts so limbs can adapt as child grows without full replacement.

- Lightweight designs that match activity levels (playing, sports, school) and are resilient.

- Integration of feedback, sensory signals and intuitive controls to help children use them more naturally.

- Real-World Connected Prosthetics & Monitoring

- Sensors for Performance & Comfort Monitoring: Prosthetics with built-in sensors to monitor things like pressure, alignment, wear and tear, temperature. These can help prosthetists adjust fitting proactively before problems (e.g. skin issues, discomfort) become severe.

- Data & Tele-Rehab: Using data from prosthetics (via apps, connected devices) to guide rehabilitation, remote check-ups, and user feedback loops. Could help make care more accessible, especially for rural or less-served areas.

- Lower Limb Innovations: Bionic Knees, Walking & Mobility

- A newly developed bionic knee that connects directly with femur, uses implanted electrodes, aims to help with stair climbing, obstacle navigation, and gives a greater sense of limb ownership. Clinical trials show improved performance.

- Bionic legs that mimic more natural joint movement (ankle, knee, multi-axis joints) and respond to environment (uneven ground, slopes) are being refined.

- Accessibility, Cost, & Inclusivity

- Companies are working on making advanced prosthetics more affordable and usable in more contexts (weather, water, rugged terrain).

- Open-source prosthetic design platforms (CAD files, local production) help communities build customised limbs.

- Designs that are inclusive (for children, for different amputation levels, for people in low-income settings) are increasingly part of the innovation push.

- Challenges & What Needs to Improve

While the innovations look promising, there are still obstacles to overcome:

- Cost and ensuring access (not everyone will benefit equally at first)

- Regulatory approvals and safety testing

- Longevity / durability of implants and interfaces

- Comfort and avoiding rejection or abandonment due to issues like pain, skin problems, or poor function

- Power / battery life, weight, maintaining usability in daily life

Final Thoughts

The near future of prosthetics is moving away from seeing artificial limbs as simply mechanical aids toward seeing them as integrated, adaptive, even living extensions of the user. As advances in materials, neural interfaces, AI, and design continue, prostheses will feel more natural, behave more intelligently, and better align with people’s lifestyles.

At Steel Bones, we believe these innovations offer real hope—not just for more mobility, but for improved comfort, independence, and quality of life. We’ll keep watching these developments, sharing what matters, and helping amputees and families access the best of what’s coming next.

Recent Comments